Campoona Graphite Delivers Above 99.9% Graphene

Adelaide, Dec 15, 2015 AEST (ABN Newswire) - Multi-resource commodity developer, Archer Exploration Limited ( ASX:AXE) has been presented with the formal report from a joint graphene research program designed to test the suitability for production into graphene of the Company's high grade Campoona graphite deposit on South Australia's Eyre Peninsula.

ASX:AXE) has been presented with the formal report from a joint graphene research program designed to test the suitability for production into graphene of the Company's high grade Campoona graphite deposit on South Australia's Eyre Peninsula.

Highlights

- University's formal findings confirm suitability of Archer's Campoona graphite on SA's Eyre Peninsula to produce world-class graphene

- Product produced under test is ultra-pure graphene above 99.9%

- Trials also successfully reduce number of chemical processes involved

- Aided by Campoona's in-situ high grade graphite profile before processing

- Several electrode types successfully tested for potential battery applications

- Initial Campoona graphene production process also proves scalable

- New 2016 trials to test full extent of scalability

- Any future graphene revenue stream additional to, not part of, current studies endorsing Campoona's profitable graphite mining start-up

The research work is funded by Archer through the University of Adelaide's School of Chemical Engineering under the direction of Professor Dusan Losic.

The aim of Archer's research is in part the development of scalable production of graphene from Campoona and broader industrial, environmental and agricultural applications for the Company's other nearby graphite deposits.

Key findings released today confirm the ability of Campoona graphite concentrates to produce pure graphene (>99.9%) with outstanding electrical properties that can be used in solar cells, photovoltaics, wearable/printable electronics, supercapacitors, batteries and sensors.

As a result, the Company now plans to continue to work with the University early in 2016 to test the extent of the scaling-up process.

Archer Managing Director, Mr Gerard Anderson, said today exhaustive studies to date had already confirmed the economic viability of Campoona as a stand-alone graphite mining operation.

"Therefore, any contribution from a new Campoona graphene production stream, which is by no means certain but does have emerging appeal, would be in addition to, not part of, the graphite profits from this Eyre Peninsula project."

Archer's hub of Eyre Peninsula graphite projects, which includes Australia's largest graphite JORC Resource, are based around three distinct graphite products, ultra-pure graphite at Campoona Shaft, Central Campoona and Lacroma, agri-business carbon at Sugarloaf, and flake graphite at Waddikee.

The Company is hopeful of having the formal Mining Lease for Campoona lodged in early 2016.

Summary of Archer-University of Adelaide Research Program

Methods and Methodology

Graphene from concentrated Campoona graphite (>99%) was prepared by the direct liquid phase mechanical exfoliation method developed by the University of Adelaide. This mechanical exfoliation process is scalable and requires fewer steps compared with the conventional methods which involve the preparation of graphene oxide then chemical reduction to produce graphene.

Results and Conclusions

(a) The process ability of graphene exfoliation process

Graphene production yield and exfoliation rates are dependent on the presence of impurities in graphite. Highly concentrated Campoona graphite (>99%) achieved high yields (>80%) and far higher exfoliation rates in producing graphene compared to a control sample (lower grade graphite concentrates grading <94% Cg) using the same process.

Archer's highly concentrated graphite (>99%) will allow for more efficient scalable graphene production compared with graphene sourced from lower grade graphite.

(b) The purity and quality of prepared graphene

Exfoliation of high purity Campoona graphite concentrate produced high quality and high-purity graphene (>99.9 %) with single to few layers. It was only possible to make such high purity graphene because of the high purity graphite sourced from the Company's Campoona project. Not all graphite can make graphene of such high purity.

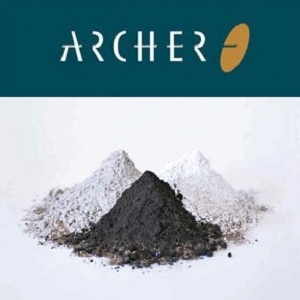

Graphene powder and graphene water dispersion products were prepared (Figure 1, see link below) which are used in the preparation of other high-value graphene based products.

(c) High-value products validation

The purity of graphene is critical for its application in high-value graphene-based products such as conductive inks, highly conductive films, flexible electronics, micro-antennas, sensors, electrodes for batteries and supercapacitors.

Several products including conductive ink, graphene conductive coating, and graphene electrodes were prepared.

Graphene Conductive Inks and Transparent Conductive Films

Prepared graphene from Campoona high grade graphite can be well dispersed in organic solvent with controllable contents (1-10 wt%) having long-term stability. The coating of inks on various substrates such as PET, PDMS, PVC, glass, quartz and metals was tested using different techniques including bar coating, spray coating, dip coating and spin coating.

The performance pf test 10wt% Graphene/PEDOT dispersed in organic solvent and coating on PET film resulted in sheet resistance of 500 Ohms/sq, a result not possible from low purity graphene (sheet resistivity >1000 Ohm/sq). The transmittance of prepared conductive film (Figure 2, left, see link below) was higher than 85%.

Even though the graphene formulation has not been fully optimised, the performance data already achieved confirms that these products are likely to be suitable for many applications including in solar cells, photovoltaics, displays, transparent electronics, 2-d printing electronic devices and sensors.

Graphene Electrodes and Wearable Antennas

Several types of electrodes were prepared to prove their electrical properties related to potential battery and wearable antennas applications. The tests returned a sheet resistance of ~ 1 Ohms/sq, corresponding to a very high conductivity of 10,000 S/m.

Prepared graphene electrodes are undergoing testing for battery development to test their performance compared with traditional graphite material.

Summary

High quality graphene can be prepared from Archer's highly concentrated Campoona graphite. Testing produced several highly valuable graphene products (inks, conductive films, electrodes). Preliminary characterisation of these products confirmed excellent electrical conductivity. These graphene-based products have enormous potential applications for solar cells, photovoltaics, wearable/printable electronics, supercapacitors, batteries and sensors.

To view the release including Figures, please visit:

http://media.abnnewswire.net/media/en/docs/ASX-AXE-897644.pdf

Contact

Greg English

Chairman

Archer Exploration

Tel: +61 8 8272 3288

Gerard Anderson

Managing Director

Archer Exploration

Tel: +61 8 8272 3288

Archer Exploration Limited

T: +61 8 8272 3288

E: info@archerexploration.com.au

WWW: www.archerexploration.com.au

| ||

|