Titomic Kinetic Fusion™ set to revolutionize high-performance pressure vessel manufacturing in collaboration with Northrop Grumman.

Titomic (ASX:TTT)

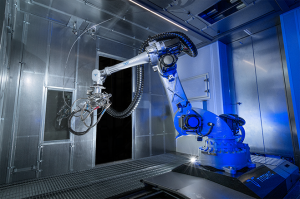

HUNTSVILLE, AL, UNITED STATES, April 16, 2025 /EINPresswire.com/ -- Titomic Limited (ASX: TTT) (‘Titomic’ or ‘Company’), a global leader in Titomic Kinetic Fusion™ cold spray additive manufacturing, is excited to announce its collaboration with Northrop Grumman to develop and manufacture high-performance pressure vessels. This work is a pivotal step in Titomic’s strategic shift toward high-value collaborations in aerospace and defense, demonstrating its commitment to delivering integrated solutions for mission-critical components.The collaboration leverages expertise in Titomic Kinetic Fusion™ cold spray systems and Northrop Grumman’s leadership in aerospace and defense, with a shared goal of enhancing the performance, durability, and significantly reducing the production schedule of critical pressure vessels. This is an initial concept development study inclusive with part production for testing to prove out for future efforts.

Titomic’s proprietary cold spray technology offers unmatched flexibility and efficiency in creating high-performance components. By eliminating the need for high-heat methods, this innovative process enhances material properties, reduces lead times, and enables complex geometries crucial for the aerospace and defense sectors. Pressure vessels, which are vital in industries like aerospace, defense, energy, and industrial applications, will benefit greatly from the enhanced strength and performance characteristics enabled by cold spray technology.

This collaboration underscores Titomic’s commitment to redefining the manufacturing landscape for critical aerospace and defense components. By leveraging localized production capabilities in the United States, Titomic is strategically positioned to meet growing demands and address global supply chain challenges. The pressure vessel market alone represents a multi-billion-dollar opportunity, and this collaboration allows both companies to capitalize on its potential.

Titomic CEO, Jim Simpson, commented on the collaboration: “We are thrilled to collaborate with Northrop Grumman to develop advanced pressure vessels using our unique Titomic Kinetic Fusion™ technology. This collaboration represents a significant step in overcoming the supply chain challenges for manufacturing of critical components for the defense industry.”

Neil Matthews AM, Senior Technical Fellow at Titomic, commented: “This collaboration with Northrop Grumman showcases the potential of cold spray technology to overcome traditional manufacturing limitations. By enabling the production of high-strength components with reduced material waste and reduced lead times, we are setting a new benchmark for aerospace and defense manufacturing. This project exemplifies the innovation that drives Titomic’s engineering efforts.”

Together, Titomic and Northrop Grumman are set to redefine the manufacturing of pressure vessels, offering a new era of durability, efficiency, and innovation that meets the demands of modern industries. This collaboration is the first in a series of initiatives that will position Titomic as a leader in the global defense and aerospace manufacturing ecosystem. Titomic is expanding its reach, diversifying its applications, and paving the way for next-generation manufacturing solutions across multiple industries.

Dr Patti Dare

Titomic

email us here

Visit us on social media:

LinkedIn

YouTube

27kg titanium valve manufactured in 4.5 hours

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.