Expansion of Research Laboratories for Pouch Cell Batteries

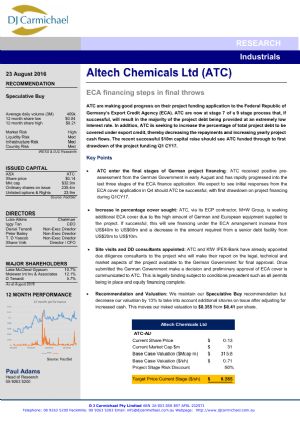

Perth, Aug 29, 2022 AEST (ABN Newswire) - Altech Chemicals Limited ( ASX:ATC) (

ASX:ATC) ( A3Y:FRA) is pleased to announce an expansion of its Research and Development Laboratories in Perth, Western Australia to allow the production of pouch cell size batteries to proceed to the next stage of the Silumina AnodesTM Project.

A3Y:FRA) is pleased to announce an expansion of its Research and Development Laboratories in Perth, Western Australia to allow the production of pouch cell size batteries to proceed to the next stage of the Silumina AnodesTM Project.

Altech announced in November last year that it had achieved the game-changing breakthrough and produced a lithium-ion battery with 30% more energy capacity than a conventional graphite-only lithium-ion battery. The Company was able to successfully incorporate alumina-coated silicon into the graphite anode of lithium-ion batteries and achieve higher energy capacity, as well as increased cyclability. The battery performance testing was conducted with the industry standard coin cell rechargeable lithium-ion batteries.

Coin battery cells provide a very useful comparison at the early research stage, but they have limitations, because of their design and construction. When developing new active material for lithium-ion batteries, the cell chemistry is first optimized in smaller format coin cells and then progressively scaled up to full-sized pouch cells to provide more information on electrochemical performance, energy density, and safety. To assess anode material against EV application targets, a scale-up from coin cell to pouch cell is necessary.

The pouch cell, a common design of a lithium-ion battery, is in a vacuum-packed thin plate shape in which many layers of thin cathode and anode electrodes are arranged. (See Figure 1). Conductive foil tabs welded to the electrode and sealed to the pouch carry the positive and negative terminals to the outside. The pouch cell pack design is used in current consumer, military, and automotive applications.

By having an in-house pouch cell production and testing facility, electrical abuse scenarios, whereby the cell is required to operate outside nominal voltage and current limitations, can be tested. Physical and environmental abuse scenarios, whereby the cell is subjected to temperature extremes or mechanical deformation, can also be tested.

Proposed Testwork

Altech plans to assemble lithium-ion pouch cells for high-power applications. Electrochemical tests will apply on both coin cells and pouch cells with the same electrode to know whether the performance measured in coin cells is representative of full-sized cells. It is also important to understand the different contributions of mechanical and thermal factors to the degradation process in each cell format. Once optimized in electrochemical properties, Altech will also undertake a safety test on pouch cells using its Silumina Anodes TM material in-house, or collaborate with external laboratories.

Expansion of Silumina AnodesTM Making Capability

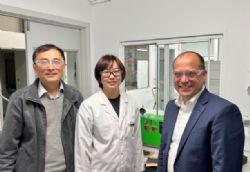

Manufacturing a pouch cell with multiple layers requires more anode material and additional cell-making equipment. During the first quarter of 2022, Altech installed and commissioned a larger-scale tube furnace in its Research and Development Laboratories in Perth. The new furnace has the capability of producing larger kilogram samples per batch.

*To view tables and figures, please visit:

https://abnnewswire.net/lnk/I2S28U93

About Altech Batteries Ltd

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) is a specialty battery technology company that has a joint venture agreement with world leading German battery institute Fraunhofer IKTS ("Fraunhofer") to commercialise the revolutionary CERENERGY(R) Sodium Alumina Solid State (SAS) Battery. CERENERGY(R) batteries are the game-changing alternative to lithium-ion batteries. CERENERGY(R) batteries are fire and explosion-proof; have a life span of more than 15 years and operate in extreme cold and desert climates. The battery technology uses table salt and is lithium-free; cobalt-free; graphite-free; and copper-free, eliminating exposure to critical metal price rises and supply chain concerns.

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) is a specialty battery technology company that has a joint venture agreement with world leading German battery institute Fraunhofer IKTS ("Fraunhofer") to commercialise the revolutionary CERENERGY(R) Sodium Alumina Solid State (SAS) Battery. CERENERGY(R) batteries are the game-changing alternative to lithium-ion batteries. CERENERGY(R) batteries are fire and explosion-proof; have a life span of more than 15 years and operate in extreme cold and desert climates. The battery technology uses table salt and is lithium-free; cobalt-free; graphite-free; and copper-free, eliminating exposure to critical metal price rises and supply chain concerns.

The joint venture is commercialising its CERENERGY(R) battery, with plans to construct a 100MWh production facility on Altech's land in Saxony, Germany. The facility intends to produce CERENERGY(R) battery modules to provide grid storage solutions to the market.

| ||

|