Youanmi Vanadium Project

Vanadium Oxide JORC 2012 Resource with Exploration Results

Perth, Mar 20, 2019 AEST (ABN Newswire) - Venus Metals Corporation Limited ( ASX:VMC) announces new JORC 2012 vanadium oxide mineral resource confirmed.

ASX:VMC) announces new JORC 2012 vanadium oxide mineral resource confirmed.

This announcement replaces the announcement on 18 March as it includes updated information in respect of the mineral resource and exploration results.

HIGHLIGHTS

- The new JORC 2012 total resource estimate is 134.73 mt grading 0.34% V2O5

- The measured, indicated and inferred resources contain 458,900 tonnes (approximately 1,011,415,600 lbs) of V2O5 (Vanadium Pentoxide)

- New JORC 2012 Vanadium Oxide Resources were calculated by Company Consultant Widenbar and Associates, based on 139 recent RC holes for 5919m and 49 historical RC and 11 Diamond holes for 3268m .

- Significantly, the large measured resource status enables Venus to confidently proceed with metallurgical testwork and scoping studies to rapidly advance the project.

PROJECT BACKGROUND

1. Venus controls a unique open pit vanadium oxide resource at Youanmi in the Midwest region of Western Australia. The resource has the potential to be a significant supplier to the world vanadium market particularly for the emerging renewable battery energy needs.

2. The project, 90% owned by Venus, is well located with respect to regional infrastructure. It is 460km east of the port of Geraldton, W.A., (see Figure 2 in link below) with a regional gas energy supply located at Windimurra, 40km northwest of Youanmi.

3. At Youanmi, the oxide resource (JORC 2012) is now 134.7 million tonnes grading 0.34% V2O5 contain 458,900 tonnes (approximately 1,011,415,600 lbs) of V2O5 (Vanadium Pentoxide).

4. The proposed vanadium extraction for Youanmi is based on a potentially simple hydrometallurgical process taking advantage of the unique weathered vanadium oxide ore, and with potentially more positive project economics compared to conventional hard rock deposits.

5. The oxide V2O5 resource occurs from surface down to 30 -50 meters depth and is the focus of initial studies for potential development.

6. The friable, crumbly soft oxide material is derived from deeply weathered vanadiferous gabbro, characteristics unique to Youanmi.

7. Being soft, the oxide material enables simple mining by open cut methods with a likely zero strip ratio.

8. Metallurgical studies show that simple beneficiation by way of low-energy crushing and desliming can markedly increase the ore grade (from 0.58% V2O5 to 0.8% V2O5) before vanadium extraction by way of leaching (ASX release 16th October 2018).

9. Initial hydro-metallurgical leach tests at atmospheric pressures show that 81.6% of the vanadium can be recovered by leaching of the oxide material using acid solutions (ASX release 29 January 2019).

10. The Youanmi oxide vanadium project is therefore very different to the highly capital-intensive pyro-metallurgical process used by traditional hard rock vanadium.

RESULTS OF RECENT INFILL DRILLING FOR RESOURCE DEFINITION PROGRAM

In December 2018, Venus completed a major resource definition infill drilling program of 139 RC holes for 5919m within a zone of vanadiferous magnetite gabbro, 2km long by 300 to 400 m wide (ASX release 13th December 2018).

The RC holes were drilled on 40x80m and 80mx120m grid patterns along 19 drill lines (see Figure 3 in link below) and are confined to the weathering zone of the resource area with the depth of the RC holes ranging from 19m to 50m (see Appendix-1 in link below).

Drilling intersected duricrust in some holes, mottled zone clay, saprolitic clay, saprock and fresh rock; most holes were stopped a few metres into fresh rock.

Sampling was at 1m intervals using a riffle splitter. All one-metre samples were submitted to a SGS Laboratory, Perth, for analysis. At the laboratory, 1826 samples were composited into 2-metre intervals. All one-metre samples (4093) and the 2-metre composites (913) were analysed using a borate fusion with XRF finish (refer Appendix 3 (see link below). JORC Table-1 in link below).

Best results include:

- 138 holes intersected zones of vanadium mineralization of more than 0.3% V2O5,

- 129 holes intersected zones of more than 0.5% V2O5 and

- 27 holes encountered zones of more than 1% V2O5 (see Appendix 2 in link below) with the maximum V2O5 concentration of 1.30% V2O5 at shallow depths in holes SC010 (15-16m) and SC015 (21- 22m).

The vanadiferous clay zones in the weathering zone broadly correlate with vanadiferous magnetite zones in the bedrock and show a shallow southerly dip.

SUMMARY OF MINERAL RESOURCE ESTIMATE

Widenbar and Associates has produced an updated Mineral Resource Estimate for the Youanmi Vanadium Deposit, located 500 km north-east of Perth.

Drilling, Sampling and Assaying

Earlier Reverse Circulation (RC) drilling at the Youanmi Vanadium Deposit was carried out by Australian Gold Resources (AGR) during 1998-1999 with most RC holes drilled vertically and a few at -60deg angle.

Drill samples were collected at one-metre intervals using a cyclone and riffle splitter. Four-metre composite analytical samples were collected from the sample bags using a scoop or spear. RC drill samples were geologically logged and the downhole magnetic susceptibility measured as per the historical report. Drill hole geological logging, assay data and metallurgical test data are used to support the vanadium resource estimate.

In 2010, a diamond drilling program was carried out by Youanmi Metals Pty Ltd comprising 11 holes (YMDD001 - YMDD011) for 637.5m. All holes were geologically logged on site and the logs were subsequently uploaded into a digital relational database (Datashed(TM)). Geological codes are those used as a standard by the Creasy Group of companies. Other relevant data collected during the logging process included structural measurements on oriented drill core, various geotechnical data (core recovery, RQD, rock strength, weathering and fracture counts), magnetic susceptibility measurements and 'Niton' XRF readings for Fe, Ti and V.

The methods used for assay analysis of historic RC drill samples are lithium meta-borate fusion XRF at AMDEL (XRF4) and fusion XRF at Analabs (X408). Blanks were inserted every 30th sample. A vanadium standard was inserted in each sample batch for holes YOUC19 to 40. No issues were reported in the historic QAQC program.

In December 2018, Venus carried out an infill drilling resource definition program; 139 RC holes for a total of 5,919m were drilled, bringing the total drilling to 199 holes for a total of 9,187m. Venus' resource definition drilling was confined to the weathered, oxide component of the resource and fresh material is not reported in the current Mineral Resource Estimate.

All Venus RC samples were analysed at SGS Australia Pty Ltd laboratories. Assays used borate fusion with XRF finish for elements including Al, As, Ca, Co, Cr, Cu, Fe, K, Mg, Mn, Na, Ni, P, Pb, S, Si, Ti, V, Zn, and LOI.

Magnetic Susceptibility (Magsus) was measured using a handheld KT-10 Magsus susceptibility meter, Magsus readings were taken in the field by handholding Magsus meter directly on to the sample bags.

Venus' QAQC procedures were carried out at SGS Australia Pty Ltd laboratories and included 126 blanks (1 in 40), 249 standards (1 in 20), 249 repeats (1 in 20) and 123 duplicates (1 in 40). No issues were reported in the QAQC program.

The drill hole database was prepared by Venus in Excel spreadsheet format. Review of printed logs versus the current database has been carried out; no issues have been reported. Data has been imported into Micromine (2018.5) software for further validation, including:

- Checks for duplicate collars.

- Checks for missing samples.

- Checks for down hole from-to interval consistency.

- Checks for overlapping samples.

- Checks for samples beyond hole depth.

- Checks for missing assays.

- Checks for down-hole information beyond hole depth.

- Checks for missing down-hole information.

- Checks for missing or erroneous collar survey.

There were a total of 263 RC and 11 DD holes in the database as provided. A total of 199 holes were in the area modelled as part of the updated Mineral Resource Estimate.

Geology and Mineralisation

Youanmi is located within the Southern Cross Province and northwest portion of the Yilgarn Craton of Western Australia. The Province is characterised by arcuate, generally northerly trending greenstone belts that outcrop between areas of granite and gneiss. The regional geology is dominated by typical Archaean granite-greenstone terrain, with the greenstone sequences dated at between c. 3.0Ga (billion years) and 2.8Ga, and granites in the range 2.95-2.6Ga. The dominant regional structures are NE trending and N to NW trending folds, faults and shear zones.

The western portion of the Youanmi Greenstone Belt comprises two parts separated by the Youanmi Intrusion, which largely occupies the combined reporting area. The northern part consists of felsic volcanics, BIF and massive dolerite, forming a gently north plunging antiform, truncated by the Youanmi Intrusion to the south (Moody, 2007). The southern part consists of deeply weathered ultramafic intrusives and felsic volcanic rocks.

The Youanmi Intrusion occupies an oval shaped area about 20 kilometres north-south by 10 kilometres east-west bounded by marginal greenstone lithologies and granitic rocks. It consists of gabbro, leucogabbro, norite, melagabbro, pyroxenite and anorthosite. Detailed aeromagnetic data indicates the uniform consistency of the stratigraphy within the complex, particularly the magnetic horizons. These horizons are offset by several major NW trending faults.

The Project area and its surrounds contain numerous multi-commodity resources including gold, vanadium, and zinc (+copper) mineral occurrences or deposits.

Known metal mineralisation in the Youanmi area consists of:

- gold: associated with faulting, shearing and alteration (hosted by most rock types)

- base metals: stratabound copper mineralisation in supracrustal rocks, cupriferous quartz veins and shears, copper-nickel sulphides in gabbroic complexes vanadium and magnetite: massive and disseminated bands in layered mafic rocks (including gabbro, leucogabbro, melanogabbro, pyroxenite, anorthosite and magnetite rich rocks).

The prominent vanadiferous titano-magnetite horizons forming a strong magnetic signature have been interpreted to be at or near the base of the Youanmi Complex. The magnetite horizon appears to consist of two prominent units (Units 1 and 2) separated by leucogabbro and magnetite rich gabbro which are remarkably uniform around the entire length of the complex. These units comprise numerous individual massive magnetite bands varying in thickness from a few centimetres to approximately one meter, separated by magnetic gabbro.

The magnetite bearing horizons appear to be more resistant to weathering and therefore the top of fresh rock is generally at a higher relative level than in adjacent weathered gabbro. Additionally, in the areas where the regolith has been stripped, the saprolite derived from magnetite-rich horizons has proven more resistant to erosion and often forms the tops of the breakaways. Depth to top of fresh rock (TOFR) in the higher ground is usually about 35m, but can be up to 55m. Petrographic analysis by AGR indicated that in the more oxidised samples magnetite is altered to martite and ultimately to hematite.

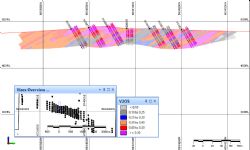

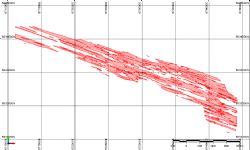

Previously, two broad mineralisation zones were recognised, varying between 30m and 50m in true thickness and dipping between at approximately 30deg to the south. The Venus infill drilling campaign has confirmed the general location of these zone, but has also highlighted the alternation of minor mineralised and waste zones within these domains.

Grade shells at 0.1%, 0.2%, 0.25%, 0.3% and 0.4% have been generated but it has been found unnecessary to use these as constraints, as there is not a clear enough grade boundary to define consistent threshold values

Down hole geological logging data has been used to generate weathering codes and 3-dimensional wireframe surfaces have been generated.

- CW - completely weathered; PW - partially weathered; FR - fresh

The surfaces are used to assign bulk density to the block model and to assist in statistical analysis.

Statistical Analysis

A review of assay sample lengths indicated a need for compositing to a one-metre interval.

Composites were flagged with weathering codes, and assay and MagSus data was merged together for further analysis.

Distribution analysis was carried out for the PW, CW and FR weathering codes and shows some differences between the weathering domains. There is a more marked difference in Magsus in the weathering domains, reflecting magnetite in the fresh material that has likely been weathered to hematite; there is significantly lower Magsus in the completely weathered material.

While there is no significant correlation between V2O5 and Magsus there are strong correlations for V2O5 vs Fe and V2O5 vs TiO2, while Al2O3 and SiO2 are negatively correlated with V2O5. Variography was carried out for all domain data, and produced reasonably robust variograms which could be in kriging interpolation. Nugget effect was low (17%) and variogram ranges were 378m along strike, 202m down dip and 16.5m across the mineralised structures.

Block Model Setup and Interpolation

Block sizes were based on approximately 1/4 drill spacing (20m E-W by 10m N-S by 2.5m Elevation) with sub-cells to a minimum of 2m x 1m x 0.5m to honour topographic and mineralisation boundaries. Blocks were rotated 20deg around the Z axis to align with the geological strike and 30deg around the X axis to align with the geological dip. Rock models were also constructed at larger block sizes (40x20x5) and smaller block sizes (5x2x2) in order to assess the effect of block size on grade and tonnage estimation.

Resource estimation was carried out in Micromine 2018.5 software. Ordinary kriging (OK) interpolation was used with parameters based on variography and drill hole spacing.

Search ellipse orientations for the estimation were based on geological orientations. The first pass search was 100m x 60m x 10m (along strike 020deg, down dip -30deg, across dip) with a minimum of 6 and a maximum of 12 composites, a maximum of 6 per hole and a minimum of 2 holes. The second pass search was 200m x 120m x 15m with a minimum of 4 and a maximum of 16 composites, a maximum of 6 per hole and a minimum of 2 holes. The third pass search was designed to fill any remaining gaps in the model and was 600m x 240m x 25m with a minimum of 2 and a maximum of 16 composites, a maximum of 6 per hole and a minimum of 1 hole.

As there has been no mining to date, no reconciliation data is available.

Bulk density is based on over 6,800 downhole density log measurements. Base of oxidation logging has been used to define two density domains, with the following bulk densities applied:

- Oxide 2.63 t/m3

- Fresh 2.76 t/m3

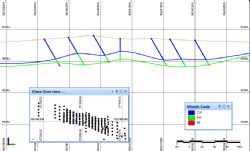

Modelling results have been compared to the previously published resource estimate and have produced similar results for the high grade domains. Validation of the final resource has been carried out in a number of ways, including:

- Drill Hole Section Comparison

- Comparison by Mineralisation Zone

- Swathe Plot Validation

- Model versus Declustered Composites by Domain

All modes of validation have produced acceptable results.

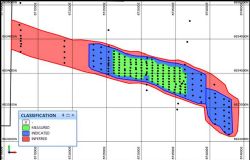

The Youanmi Vanadium Mineral Resource has been classified in accordance with The 2012 Australasian Code for Reporting of Mineral Resources and Ore Reserves (JORC Code). A range of criteria have been considered in determining this classification including:

- Geological continuity;

- Data quality;

- Sample spacing;

- Modelling technique.

Geological Continuity

The classification reflects a high level of confidence in the nature and location of the Vanadiferous mineralisation.

Data Quality

Resource classification is based on information and data compiled by Venus. Descriptions of sampling techniques indicate that data collection and management by previous owners and by Venus has been reasonable. The data is considered adequate to support the classifications proposed.

Sample Spacing

There is a sufficient spread of drill holes both along strike and down dip in the oxide portion of the deposit to support the proposed classification.

Modelling Technique

An Ordinary Kriging estimation methodology has been used for calculation of grades. Additional output from the kriging process (kriging variance, numbers of samples, average distance to samples, kriging efficiency and slope of regression) have also been generated and used to assist in classification definition.

Final Classification

Preliminary metallurgical work has that indicated that the oxide portion of the Youanmi Vanadium Deposit can be economically processed and thus represents a viable resource.

The Youanmi Vanadium Mineral Resource has been classified in the Measured, Indicated and Inferred categories in accordance with the 2012 Australasian Code for Reporting of Mineral Resources and Ore Reserves (JORC Code). The Mineral Resource Estimate is confined to the he oxide portion of the deposit. Widenbar has reviewed the drilling, sampling and assaying data used in the estimate and considers it to be of sufficient quality to support the resource classification applied.

FORWARD PROGRAM

Further development of the hydro-metallurgical process is being planned and contracts have been prepared with a renowned Metallurgical Process Development team of experts to implement this strategy.

Venus is planning and scheduling the following project development stages:

- Intensive hydrometallurgical studies and pilot scale development,

- Further drilling to define a mining reserve as well as target drill the additional 25km of mineralized strike

- Scoping studies, prefeasibility studies, marketing studies, environmental studies, definitive engineering studies and all other works to rapidly advance the project.

Mr Matthew Hogan, Managing Director of Venus Metals commented

"We are very pleased with this result that fully justifies our decision to proceed with a comprehensive drill-out of our vanadium project at Youanmi. As the world transitions into a low-carbon future it will require significantly more power storage capacity. Vanadium is a sustainable metal allowing unlimited storage life and capacity for clean energy as well as stronger, lighter and more resilient steels and alloys for infrastructure and transport. Vanadium is currently at the forefront of technology innovation yet it is in short supply. With our now proven world-scale resource base at Youanmi, we believe we have the potential to unlock the project with new processing technology advancements in vanadium extraction from oxide ore".

To view tables and figures, please visit:

http://abnnewswire.net/lnk/P353KB62

About Venus Metals Corporation Limited

Venus Metals Corporation Limited (ASX:VMC) is a West Australian based Company with a focus on gold, base metals, vanadium and lithium exploration projects. The Company aims to increase shareholder value through targeted exploration success on its projects.

The Company's major gold project is the Youanmi Gold Mine, located 500km north-east of Perth. The Youanmi Gold Mine is now jointly owned by Venus Metals (30%) and Rox Resources Limited (70%); Indicated and Inferred Resource of the mine is in excess of 3 million ounces of gold.

| ||

|