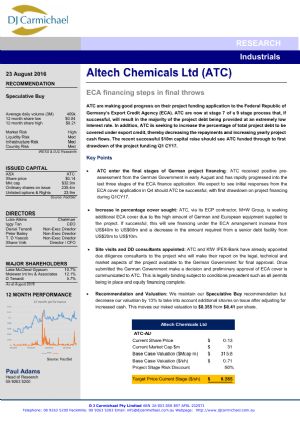

$8.1m Share Placement and initiation of SPP

Perth, Dec 2, 2021 AEST (ABN Newswire) - Altech Chemicals Limited ( ASX:ATC) (

ASX:ATC) ( A3Y:FRA) is pleased to announce the successful completion of a $8.1 million (before costs) share placement (Placement) following strong demand. The Company led placement (without a lead broker) was oversubscribed, with strong demand and interest.

A3Y:FRA) is pleased to announce the successful completion of a $8.1 million (before costs) share placement (Placement) following strong demand. The Company led placement (without a lead broker) was oversubscribed, with strong demand and interest.

The Company will also initiate a Share Purchase Plan (SPP) whereby existing shareholders can apply for up to $30,000 of new Altech shares at the same price as the Placement participants. The Placement and SPP shares will be issued at a price of 10.7 cents per share, representing a 24% discount to the price of the Company's shares as traded on the ASX at the close of trade on Monday 29 November 2021, which was 14.0 cents per share (and 19.5% discount to the 5 day VWAP at the close of trade on Monday 29 November 2021). The Placement shares will be issued in a single tranche under the Company's current share placement capacity pursuant to ASX Listing Rule 7.1. Approximately 76 million shares will be issued pursuant to the Placement.

Proceeds from the Placement will be applied to Altech's 75% portion of funding the construction of a battery materials coating pilot plant in Germany by Altech Industries Germany GmbH; purchase of land at the Schwarze Pumpe Industrial Park; completion of the preliminary feasibility study in relation to the construction of a 10,000tpa battery materials plant; a definitive feasibility study for construction of a battery materials plant, and for working capital purposes.

Altech has been successful in applying its alumina coating technology to both silicon and graphite particles, typical of those used in the anode of lithium-ion batteries, such as in the burgeoning electric vehicle industry. Alumina coated particles, when incorporated into a lithium-ion battery anode would improve battery energy capacity, life and performance. On 25 November 2021, the Company announced a significant breakthrough achieved by its research and development laboratory located in Perth, Western Australia. After almost 12 months of challenging work, the R&D team "cracked the silicon barrier" and successfully produced a series of lithium-ion battery anode materials, which when tested showed ~30% higher energy retention capacity compared to conventional lithium-ion battery anode materials.

To achieve its breakthrough, Altech successfully combined silicon particles that had been treated with its innovative proprietary coating technology with regular battery grade graphite particles, to produce a lithium-ion battery electrode containing a composite graphite / silicon anode. When energised, these materials held 30% more capacity compared to a conventional graphite only anode material. Also, the previously unresolved obstacles for using silicon in lithium-ion battery anodes were silicon particle swelling; prohibitive first-cycle-capacity-loss of up to 50%; and rapid battery degradation from each charge and discharge cycle, each of these were also resolved during the laboratory testing of Altech's composite graphite/silicon battery anodes. Importantly, the batteries demonstrated extremely good stability and cycling performance over extended periods.

The lithium-ion battery industry has recognised that the required step change to increase lithium-ion battery energy density and reduced cost is to introduce silicon into battery anodes, as silicon has ~ ten times the energy retention capacity compared to graphite. Silicon metal has been identified as the most promising anode material for the next generation of lithium-ion batteries. However, until now, silicon was unable to be used in commercial lithium-ion batteries due to two critical drawbacks. Firstly, silicon particles expand by up to 300% in volume during battery charge, causing particle swelling, fracturing and ultimately battery failure. The second challenge is that silicon deactivates a high percentage of the lithium ions in a battery. Lithium ions are rendered in-active by the silicon, immediately reducing battery performance and life. The industry has been in a race to crack the silicon barrier.

Altech's potentially game changing technology has demonstrated that silicon particles can be modified to resolve the capacity loss caused by swelling and first-cycle-loss capacity. Phase 2 of Altech's planned R&D program will see the Company strive to improve on the 30% energy increase achieved in the first phase. The Company has commenced a preliminary feasibility study (PFS) for the construction of a battery materials coating plant in Saxony, Germany. The PFS is being undertaken by Altech's 75% owned German subsidiary, Altech Industries Germany GmbH (AIG) and is nearing completion. Altech has also commenced an independent green accreditation of the process.

Share Purchase Plan

The share purchase plan (SPP) will be open to all existing Altech shareholders with a registered address in Australia or New Zealand, who were recorded on the Company's share register at 29 November 2021 (record date). Participation in the SPP is optional, however any shares purchased via the SPP will not incur any brokerage or other transaction costs.

Based on the positive response from the previous SPP that the Company undertook in December 2019, an additional $4.0 million could be expected to be raised from this SPP. Funds raised from the SPP will also be applied to the development of the battery materials project. All new shares issued under the SPP will rank equally with existing ordinary shares of the Company.

The closing date for participation in the SPP will be Friday 17 December 2021. Full details of the SPP and individual letters including acceptance forms will be mailed to all eligible shareholders on Monday 6 December 2021.

*To view the Timetable, please visit:

https://abnnewswire.net/lnk/XJN84VQZ

About Altech Batteries Ltd

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) is a specialty battery technology company that has a joint venture agreement with world leading German battery institute Fraunhofer IKTS ("Fraunhofer") to commercialise the revolutionary CERENERGY(R) Sodium Alumina Solid State (SAS) Battery. CERENERGY(R) batteries are the game-changing alternative to lithium-ion batteries. CERENERGY(R) batteries are fire and explosion-proof; have a life span of more than 15 years and operate in extreme cold and desert climates. The battery technology uses table salt and is lithium-free; cobalt-free; graphite-free; and copper-free, eliminating exposure to critical metal price rises and supply chain concerns.

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) is a specialty battery technology company that has a joint venture agreement with world leading German battery institute Fraunhofer IKTS ("Fraunhofer") to commercialise the revolutionary CERENERGY(R) Sodium Alumina Solid State (SAS) Battery. CERENERGY(R) batteries are the game-changing alternative to lithium-ion batteries. CERENERGY(R) batteries are fire and explosion-proof; have a life span of more than 15 years and operate in extreme cold and desert climates. The battery technology uses table salt and is lithium-free; cobalt-free; graphite-free; and copper-free, eliminating exposure to critical metal price rises and supply chain concerns.

The joint venture is commercialising its CERENERGY(R) battery, with plans to construct a 100MWh production facility on Altech's land in Saxony, Germany. The facility intends to produce CERENERGY(R) battery modules to provide grid storage solutions to the market.

| ||

|